Commercialization of Open Source Hardware: Turning Open Designs into Profit

In this post, we take a closer look at cases of Open Source Hardware (OSH) projects that have successfully been commercialized.

Written by J.C. Mariscal-Melgar, Manuel Moritz, Tobias Redlich

Open Source Hardware (OSH) empowers creators and users alike by making the designs of physical objects — be it machines, devices, or any tangible products—freely available to the public. The Open Source Hardware Association (OSHWA) defines OSH as artifacts whose blueprints are accessible, allowing anyone to construct, tweak, replicate, and distribute these items. OSH is not just about sharing for the sake of community; it's about opening doors to innovation and potential income.

A crucial issue of OSH is the potential for monetary gain from designs. While OSH invites collaboration and sharing, it also supports entrepreneurs and creators in their quest to derive financial benefits from their contributions. The notion that OSH is incompatible with commercialization is a misconception; in fact, OSH designs may be manufactured for profit.

Licenses are pivotal in ensuring the commercialization rights of OSH by all parties. These licenses vary widely. On one end, reciprocal licenses such as the CERN Open Hardware License (CERN-OH) and the General Public License (GPL), alongside the TAPR Open Hardware License (OHL), mandate that modifications and shared designs contribute back to the community, imposing no restrictions on commercial or distribution activities. Conversely, permissive licenses, exemplified by the MIT License and Creative Commons Attribution, permit creators to maintain exclusive rights over derivative works but do not impose that shared designs must be contributed back. Licenses that limit commercialization or the rights to use, modify, reproduce, or distribute, like CC Non-Commercial, do not align ideologically with the principles of Free/Libre and Open licenses.

OSH designers have various avenues for sharing their work. Git forge repositories such as GitHub, GitLab, and Codeberg serve as popular platforms for hosting and collaborating on OSH projects. Additionally, dedicated websites like Thingiverse provide specialized spaces for OSH communities to exchange reproducible designs and ideas.

A closer look at OSH commercialization

Commercialization efforts of companies like SparkFun and Adafruit are evidence of the viability of OSH in the market. Founded in 2003 and 2005, respectively, the companies embraced open electronic parts to fulfill the growing market of personal fabrication. Available designs in the maker community and the shared ethos of innovation can not only cut costs but also democratize technology, echoing the collaborative spirit that would later propel the Arduino revolution into educational circles. The narrative of market advantage unfolds with strategic moves such as those of Prusa Research and FarmBot. Starting in 2012, Prusa carved out a niche in the 3D printing market with its open source printers, while in 2013, Farmbot ventured into open source precision agriculture. Both companies tapped into the zeitgeist of customization, offering consumers products tailored to their unique needs, securing a competitive edge in their respective domains and customer loyalty.

Community engagement, similarly, has been important to OSH since the early days. The RepRap project, conceived in 2005 at the University of Bath, and the Arduino platform, introduced in 2005 (building on the work of Hernando Barragan. Wiring creator), stand as examples of the power of community participation. These open source projects cultivated communities that were not just consumers but co-creators and enthusiasts who would champion the brands and drive the cycle of improvement that became synonymous with the open source movement.

The market trends of the 2010s have played into the hands of OSH, with consumers increasingly valuing sustainability, repairability, and personalization. Platforms like Thingiverse or Instructables were established and have become the digital commons where users share and refine designs. This shift towards transparent and customizable products was less a fleeting trend and more a reflection of a profound change in consumer behavior change that OSH was primed to address.

Navigating the challenges of quality and community contributions, companies like Seeed Studio and OSH Park, both born out of the DIY community, have also illustrated the importance of setting clear guidelines. OSH projects can be manufactured by other companies rather than the original developers; however, this poses a challenge in regards to the functionality, safety, and quality control of some projects. Endeavors must find ways to maintain product integrity while embracing the flood of community-driven innovation to prove that with the right processes, the open source model can indeed be a boon for business.

As we look back over the past two decades, the story of OSH is one of a quiet revolution that has reshaped how products are designed, manufactured, and consumed. From the early days of the 3D printer revolution, to the far reaching digital fabrication revolution, OSH has been a sustainable, innovative, and community-focused force. It's a narrative of transformation, driven by the vision of open collaboration and the relentless pursuit of a more participatory and transparent world.

Monetizing OSH: Can You Make Money? And if so, how?

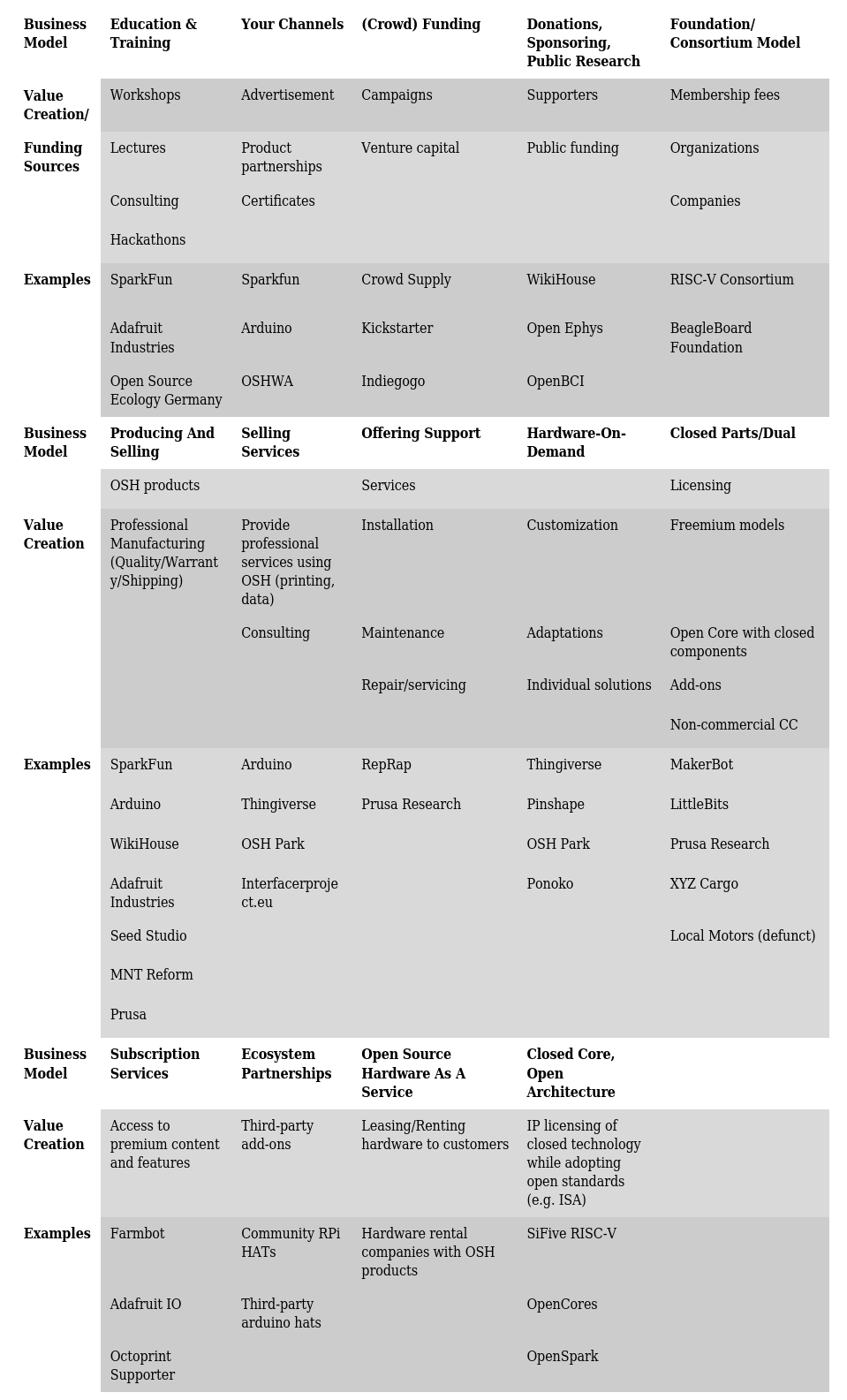

The question then arises: is it feasible to earn money with OSH? The answer is a resounding yes. OSH does not restrict profit-making; it provides users more freedom, which can be a unique selling point. Designers have the option to commercialize OSH through various channels, as illustrated in the table below (based on our previous work).

Open Source Hardware (OSH) presents a diverse ecosystem of business models, each catering to different aspects of the hardware development and distribution process. From direct sales of OSH products to offering specialized services and engaging in partnerships, these models showcase the versatility and potential. The ability to sell products directly, such as through professional manufacturing or hardware-on-demand services, could provide a straightforward revenue stream. Meanwhile, more nuanced models like subscription services for premium content or ecosystem partnerships offer ongoing revenue opportunities that capitalize on the community and network effects inherent to OSH.

The unique value proposition of OSH lies in its openness and community-driven nature, which fosters innovation, collaboration, and rapid iteration. This openness not only accelerates product development but also creates opportunities for customization and adaptation to niche markets, which are often underserved by traditional hardware companies. Transparency and trust can be leveraged as a significant selling point, attracting customers and partners who value these principles. This approach enables OSH businesses to differentiate themselves in a crowded market, offering unique products and services that are difficult to replicate by competitors operating under closed models.

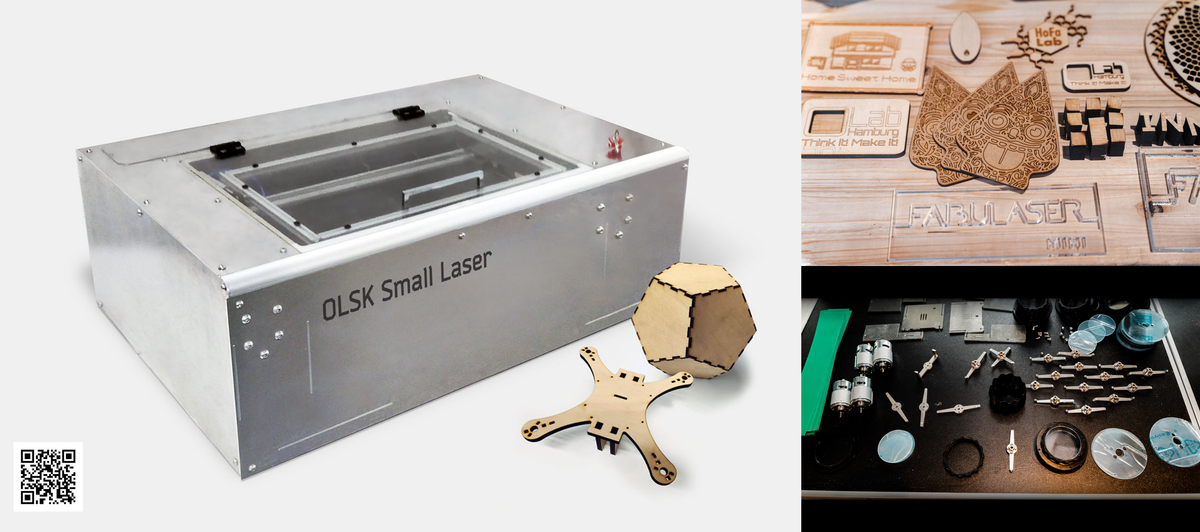

OSH machines: The case of the OLSK

Research initiatives like the Open Lab Starter Kit (OLSK) in collaboration with InMachines, created a set of 8 open source digital fabrication machines—including a laser cutter, CNC, 3D printer, 3D scanner, and vinyl cutter enable people to explore the full spectrum of manufacturing possibilities. These machines are part of the broader OpenLab project, which aims to establish FabLabs equipped with open source tools worldwide. In Hamburg, for example, the OLSK machines are not only used for educational purposes but also serve as a catalyst for community-driven innovation. By providing access to such tools, OpenLabs empowers individuals to create and share their own designs, from custom furniture to intricate machine parts.

Figure 1: OLSK Machines

Open Source digital fabrication machines allow the commercialisation of in-house designs for places with a minimal manufacturing capability for prototypes or custom-made end-user projects. The nature of OSH machines also allows for the theoretical expansion of operations, as OSH machines can reproduce themselves too.

The OLSK machines are designed with a focus on replicability and longevity, embodying the core principles of OSH. This design philosophy ensures that these machines are built to last and adaptable, allowing users to modify or replicate them according to their specific needs. Such adaptability is particularly valuable to educational institutions and makerspaces, which often require equipment that can be tailored to a wide range of educational, creative, and engineering projects.

The model for OLSK machines is centered around providing custom engineering prototypes to educational institutions or makerspaces. This strategy is further enhanced by offering workshops and actively promoting the benefits and potential of OSH. By targeting these niche markets, we capitalize on the selling point of OLSK machines: their customizability, open source nature, and educational value. These workshops play a crucial role in spreading awareness about the significance of open source hardware, thereby fostering a community of enthusiastic users and contributors.

Despite OSH's innovative approach and significant potential, several challenges could hinder broader adoption and commercial success. One of the primary challenges for new entrants is the higher cost of production compared to mass-produced alternatives. The bespoke, low-volume nature of OSH, such as the OLSK, means that they do not benefit from economies of scale, leading to higher manufacturing costs and, consequently, higher purchase prices. This can restrict their accessibility, particularly for smaller educational institutions or independent makerspaces with limited budgets. If OSH is able to overcome the initial stages of direct manufacturing commercialization, there is a chance of success.

Moreover, the challenge of obtaining CE certification poses a significant obstacle. CE marking is a mandatory conformity mark for products sold within the European Economic Area (EEA), signifying compliance with health, safety, and environmental protection standards. OSH designs, which emphasize replicability and the potential use of substitute parts, complicates the CE certification process. The open design encourages modification and customization, which can make it difficult to adhere to harmonized standards consistently. This issue is particularly acute for complex machines with stringent safety standards, such as laser cutters.The variability introduced by substitute parts and the inherent complexity of these machines makes ensuring consistent compliance with the necessary regulations a daunting task, thereby posing a barrier to their commercialization and widespread use or replication.

Several strategies could be explored to address these challenges. Collaborating with regulatory bodies to establish clear guidelines for the certification of open source hardware could simplify the process for OSH. This could involve developing a framework that accommodates the unique aspects of open source hardware, such as the use of substitute parts and the potential for user modifications. Additionally, exploring innovative manufacturing techniques or partnerships could help reduce production costs, making OLSK machines more accessible to a broader audience. For example, leveraging distributed manufacturing networks or crowd-sourced funding models could offset some of the financial challenges associated with low-volume production.

Acknowledgments

The authors would like to thank dtec.bw – Digitalization and Technology Research Center of the Bundeswehr, FabCity project, for their support.

Authors

J.C. Mariscal-Melgar, M.Sc.: Research Associate at the New Production Institute of Helmut-Schmidt University in Hamburg, Germany. His primary research interests are in sustainability, digital empowerment, and the improvement of Free/Libre software and Open Source Hardware. He develops tools, software, and policy/theoretical frameworks to support these areas.

Dr.-Ing. Dipl-Ing. Manuel Moritz, MBA: Senior Researcher at the New Production Institute of Helmut-Schmidt University in Hamburg, Germany. His research focus is on value creation systematics in connection with Fab City and Open Source Hardware.

Dr.-Ing. Dipl.-Wirt.-Ing. Tobias Redlich, MBA: Academic Director at the New Production Institute of Helmut-Schmidt University in Hamburg, Germany. His research focuses on value creation systematics and the impact of new value creation patterns on production engineering and production management.